Editor's Note: This article has been contributed by BryanCampbell, a member of the subrogation and recovery department atCozen O'Connor.

Editor's Note: This article has been contributed by BryanCampbell, a member of the subrogation and recovery department atCozen O'Connor.

Yearly, many oil pipelines fail, spill crude oil, and causesignificant health and environmental damage all across thecontinental United States, leading to hefty financial implicationsfor the oil companies, landowners, government, and insurers.

|Case in point: In September 2012, Enbridge Energy paid a $3.7million penalty for a 2010 rupture of a pipeline that polluted theKalamazoo River with thousands of gallons of crude oil. In October,Montana landowners filed suit claiming a major petroleumdistributor overlooked warnings before a pipeline break dumpedroughly 1,500 barrels of crude oil into the Yellowstone River.

|Here, we will examine the risks of pipeline spills and theirorigins, technology and regulations to mitigate potential fallout,and recovery from failure.

|The Fallout of a Spill

When oil spillsoccur, there can be significant health consequences as exposure tooil has been linked to various forms of cancer and geneticmutations in DNA that can lead to birth defects. It also goeswithout saying that oil spills have significant adverse effects onthe environment.

Because of these tremendous risks, it is imperative that oilspills are controlled, contained, and cleaned up quickly tomitigate the health/environmental risks and exorbitant financialimplications for landowners, government, and insurers. Cleanup andcontainment of oil spills—which often happen in remote,hard-to-access locations—call for specialists, extensive testing,and a process that often costs into the millions of dollars. Forthese reasons, much research and development has been dedicated topreventing oil spills from happening in the first place.

|Curbing Pipeline Failures

Even one smalloil spill can have various, far-reaching implications. Therefore,keeping these pipelines safe is critical. It is important tounderstand the origins of pipeline failures, which differ widelydepending on several factors: the environment the pipe was in,coatings used on the pipe, materials being transported, and humanerror related to lack of maintenance.

In particular, corrosion plays a significant role. Mostpipelines are manufactured from steel, which is highly corrosivewhen exposed to the soil on the outside. They are also subject todegradation on the inside through years of crude oil flowingthrough.

|Several new techniques and technological developments have madethe extraction of oil in hard-to-reach places easier, less costly,and more efficient—the result of which may be a contingency of newpipelines being built throughout the country, such as the highlycontroversial Keystone XL pipeline. While it is vital for us toemploy practices and technologies that will minimize the risk ofpipeline failures, it is equally critical to understand potentialcracks in these methods.

|Currently, in an effort to combat corrosion, most pipelines are“cathodically protected” (CP) on the outside of the pipe prior tobeing buried in the ground. CP is a technique that turns the steelpipe into the cathode of an electrochemical cell. On pipelines, CPis achieved by using a DC power source and pumping electricity intothe system. The positive cable is attached to the anode that isbackfilled into the surrounding sediment near the cathode. The pipeis connected to the negative cable, thus creating the cathode.

Although CP protection is designed to be impermeable, there aresome weaknesses. Specifically, if the CP is improperly administeredthen the production of hydrogen ions may commence, which results inthe ions being absorbed by the metal causing hydrogenembrittlement. Hydrogen embrittlement causes weakened welds andsignificantly compromises the piping itself, leading to cracks,fissures, and ultimately catastrophic oil leaks. Therefore, what isat first supposed to be a protectant ends up being the crux of itsdeterioration.

|Another advancement being applied to pipelines in an attempt toprevent ruptures is the application of a fusion-bonded epoxy (FBE)coating, which is used because it is extremely durable and canwithstand the punishment of installation, backfilling, and groundmovement. With both CP and FBE, blowouts should, theoretically, bea risk of the past. Unfortunately, however, they are not. Whenfaced with a leak on a newer pipeline, it is imperative to engagean expert who understands CP and FBE, including how they areadministered and potential problems with their application.

|In addition to new technologies making the pipelines physicallysafer, regulations are also becoming more prominent, althoughcompliance and regulatory enforcement is lacking. Laws such as 49CFR 192.112 have provided a framework for inducing safer modes ofoperation. This specific piece of regulation provides requirementsfor corrosion control and federal safety standards of natural andother gas pipelines.

|There are also regulations determining what kind of loads thepipes can carry and the pressure at which certain materials arepassed through the pipe, as well as mandatory maintenance, service,and inspection schedules.

|The combination of technology and better regulation has resultedin the safer operation of pipelines. However, significant failurescontinue to occur, such as the Kalamazoo River spill. The problemmay not simply be the lack of regulation, but also the partiesresponsible to enforce and/or comply with the regulations. ThePipelines and Hazardous Materials Safety Administration (PHMSA) isfrequently short of inspectors, leaving the regulatory inspectionup to the pipeline operators, which may pose a conflict ofinterest. Because of the inadequate inspection by the PHMSA, thereis a lack of answers as to why recent blowouts haveoccurred.

|Consequently, the derisory inspection capabilities provided bythe PHMSA instill doubt to pipeline safety. Without tougherinspections, penalties, and increased adherence to the regulations,pipeline blowouts may never be truly eradicated.

|Recovering from a Spill

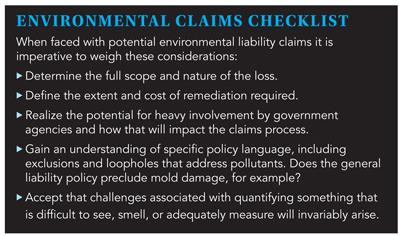

Despite new technologies and regulations making pipeline operationssafer, improper application of coatings, unplanned reaction ofchemicals, and other factors can induce disastrous blowouts leadingto environmental damage and property loss. Chances of breakdownalso increase with imperfect execution of perfected procedures bythird parties, i.e. workers, manufacturers, installers, andoperators.

This is where there is potential for subrogation—but time is ofthe essence. Investigation into causation and proper cleanup movequickly and involve highly technical issues. Retaining propertyexperts and consultants early on can make a significant differencein recovering from pipeline failure.

|Want to continue reading?

Become a Free PropertyCasualty360 Digital Reader

Your access to unlimited PropertyCasualty360 content isn’t changing.

Once you are an ALM digital member, you’ll receive:

- All PropertyCasualty360.com news coverage, best practices, and in-depth analysis.

- Educational webcasts, resources from industry leaders, and informative newsletters.

- Other award-winning websites including BenefitsPRO.com and ThinkAdvisor.com.

Already have an account? Sign In

© 2024 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.